Current Location:Home Page >About Us >Company Profile

-

Quality

Fine production, intelligent manufacturing, provide you with professional and mature industrial furnace equipment and environmental protection equipment in related industries. -

Innovation

Never-ending technological innovation, assisted by dozens of patents, make every device ingenious -

Service

From consultation to after-sales, the whole process, all-round and dedicated service system will protect you

介_(kāi)02_optimized.jpg)

Huzhou Henghui Technology Co., Ltd.

Huzhou Heng Hui Technology Co., Ltd. (formerly known as Huzhou Heng Hui Industrial Furnace Co., Ltd., renamed in June 2016), is a professional domestic manufacturer of industrial furnaces and thermal equipment. The company boasts a comprehensive range of technical expertise and strong core technological capabilities, integrating R&D, product design, manufacturing and installation, as well as independent development of core electrical control systems and software. With years of manufacturing and construction experience, standardized construction processes, and stable, reliable equipment operation, it has built a solid reputation in the industry.

In the field of core technologies, the company has dedicated itself to continuous innovation, achieving multiple national invention patents and utility model patents in areas such as rapid quenching systems for high-manganese steel and other steel castings, large heavy-duty segmented variable-volume gas car-type heat treatment furnace technology and sealing technology, wind-circulating shot blasting equipment, and catalytic combustion-type paint drying equipment. Additionally, it holds multiple software copyrights for computer control systems for heat treatment and heating furnaces. These core technologies are now maturely applied to its main products, combined with computer control technology to further enhance operational stability and intelligence.

The company specializes in providing customized heating furnaces, heat treatment furnaces, and related environmental protection equipment for industries such as heavy equipment, construction machinery, casting and forging, nuclear power equipment, chemical containers, power generation equipment, aerospace, military manufacturing, and shipbuilding. Its heating furnaces include car-type heating furnaces, chamber heating furnaces, and pusher-type heating furnaces. Heat treatment furnaces include rapid quenching furnace systems with supporting loading and unloading systems for the casting industry, large heavy-duty variable-volume car-type gas heat treatment furnaces for the equipment industry, vertical quenching furnaces for aluminum alloy heat treatment, and roller annealing hood-type furnaces. Particularly outstanding are its rapid quenching furnace systems for high-manganese steel and stainless steel in the casting industry with supporting forklift loading and unloading systems, high-precision gas heat treatment furnaces for the head-making industry, large heavy-duty variable-volume car-type gas heat treatment furnaces for the heavy equipment and pressure vessel industries, wind-circulating shot blasting equipment, and catalytic combustion-type paint drying equipment, which have gained recognition and praise from numerous clients for their stable performance and reliable quality.

In addition to supplying core products, the company also offers professional industrial furnace energy-saving maintenance services. It conducts comprehensive and professional analysis and testing of existing industrial furnace issues, proposing integrated energy-saving optimization measures from design, production, and management perspectives. It also provides upgrading services for key combustion system equipment and control systems, offering comprehensive retrofitting solutions for outdated industrial furnaces to help owners reduce energy consumption and improve product quality. In recent years, newly developed rapid quenching units and high-speed regenerative burners have been applied to heating furnace and high-temperature heat treatment furnace retrofitting projects for multiple enterprises, effectively helping customers enhance production efficiency, reduce operating costs, and improve core economic benefits.

While steadily improving its existing market layout, the company continues to explore new markets and enhance its core competitiveness, actively strengthening close cooperation with high-quality domestic and international enterprises. By introducing advanced heat treatment furnace projects and technologies and leveraging its own R&D and manufacturing strengths, the company absorbs, innovates, and upgrades advanced technologies to provide customers with more competitive high-end heat treatment and heating equipment, along with supporting technical services.

Integrity is the foundation of the company’s survival and development. Since its establishment, Heng Hui Technology has consistently adhered to the principle of honest operation, delivering on its promises regardless of the scale of the customer or project. It maintains a rigorous and responsible attitude, strictly controlling product quality and service processes in accordance with national and industry standards, thereby building a strong reputation in the industry.

Moving forward, Heng Hui Technology will continue to leverage its pioneering spirit and innovative capabilities, deepen its expertise in the field of industrial furnaces and thermal equipment, continuously improve product and service quality, provide customers with superior and more efficient solutions, bring greater pride and honor to all employees, and contribute to the high-quality development of the industry.

Company Culture

-

Integrity First

Integrity is fundamental to being a person, and it is also the cornerstone of a company's survival and development. Since its inception, our company has always adhered to the principle of integrity, keeping our promises and delivering results. Regardless of the size of our clients or the scale of the project, we maintain a rigorous and responsible attitude, strictly controlling product quality and service processes in accordance with national and industry standards, earning a good reputation in the industry.文化_03.jpg)

-

文化_07.jpg)

Dedication

From leadership to ordinary employees, the company strictly abides by its positions and works diligently. "Willing to work hard, willing to pay, not afraid of suffering, without complaints" is the most true portrayal of Henghui people. These due diligence styles are inherited by the old employees and have a new expression in the young employees, infused with new content. -

Innovation

Since its establishment, the company has been striving in the market, accumulating experience from successes and learning lessons from failures. In the fierce and complex market environment, it constantly summarizes experience, learns humbly, improves technical skills, enhances service quality, and has won a large market share in fierce competition. Based in Changxing, known as the "Hometown of Electric Furnaces," Henghui Technology stands as an innovative practitioner in the local industrial furnace sector, bold in experimentation and scientific innovation. The company possesses the capability to independently handle the entire process of designing, manufacturing, installing, and electrically controlling large-scale gas heat treatment furnaces and heating furnaces, as well as on-site installation and commissioning, positioning it as a professional industrial furnace manufacturing enterprise. It has developed and designed regenerative combustion systems, independently researched and produced rapid quenching units for high manganese steel and alloy steel, achieving a quenching transfer time from the furnace of less than 30 seconds. Additionally, the company possesses independent capabilities in the development of industrial furnace control software. In the future journey, Henghui Technology will continue to leverage and develop its pioneering spirit and innovation capabilities, deeply explore the development of the industrial furnace industry, adhere to technological innovation, provide customers with higher-quality products and services, and also win more pride and honor for Henghui people.

-

Brand Services

The company adheres to the business philosophy of "focusing on customer needs", regards "integrity as life", puts customer needs first; strictly controls product quality and service quality and implements "nanny service". Users can enjoy on-demand product after-sale tracking service for life. The company has a dedicated after-sales service department to provide users with first-class integrated services and quality with better strength. -

文化_12.jpg)

Corporate Vision

Work hard, keep improving, and work together for a common goal.

Based on the field of industrial furnaces, to achieve co-creation, win-win and sharing among customers, employees and enterprises.

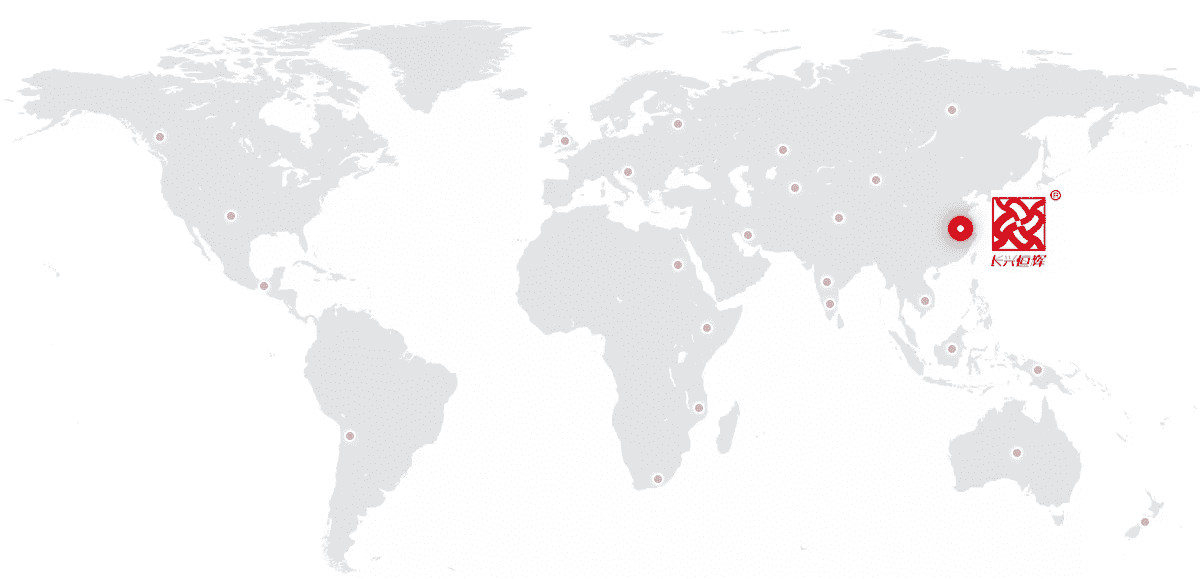

Marketing Network

介1_03.jpg)